Prefabricated

Buildings

The Pre-Engineered steel structure are designed for resistant to moisture, adverse weather conditions, earthquake, termites & fire that provide you with lifelong durability, safety & very low cost of maintenance. Pre-engineered steel building is a very simple and economical with the necessary Architectural, Engineering & Construction with Pre-engineered steel Buildings.

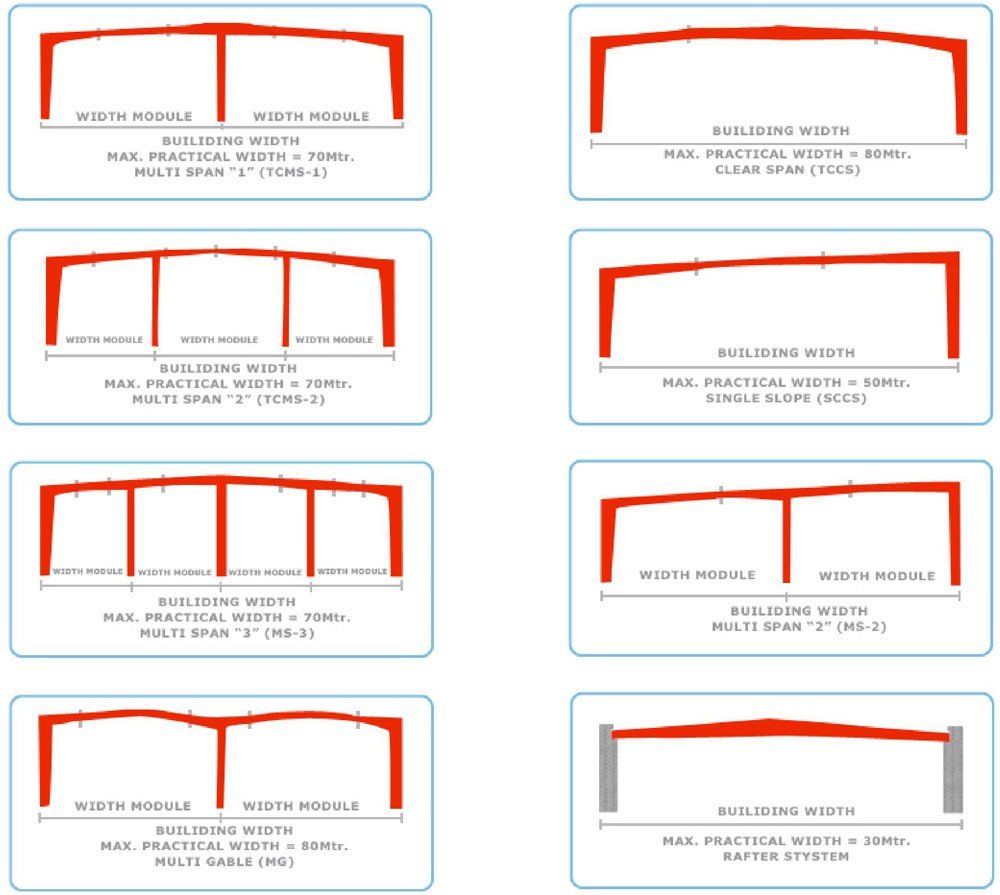

A metal Building system is selected for the Project at hand, the next milestone is choosing among the available types of Pre-Engineered primary framing. Proper selection of primary framing, the backbone of Metal Buildings, goes a long way toward a successful implementation of the design steps to follow.

Some of the factors that influence the choice of Main Framing include:

- Dimension of Building: Width, Length & Height

- Roof Slope

- Required column- free clear Spans.

- Occupancy of the Building and acceptability of exposed steel columns

- Proposed Roof & wall materials.

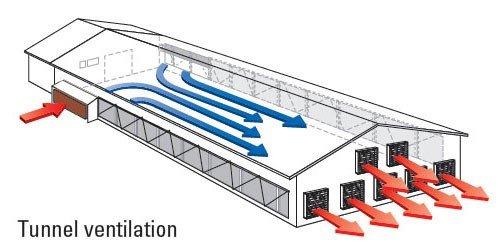

Poultry shed/farm for broiler layer breeder chicken design.

- This style of poultry house is widely used for its convenience and low-cost.

- Light steel structure

- Easy to assemble and disassemble for several times without damage.

- The steel structure adopts hot-DIP galvanized steel

- The product not only has benefits of rust protection, acid resistance, good insulation performance, but also neat and artistic. What’s more, the steel structure is also famous for its conformation with the principles of physics, easy structure, high efficiency, lower cost, great flexibility, fire and wind protection, lighting, and shock protection.

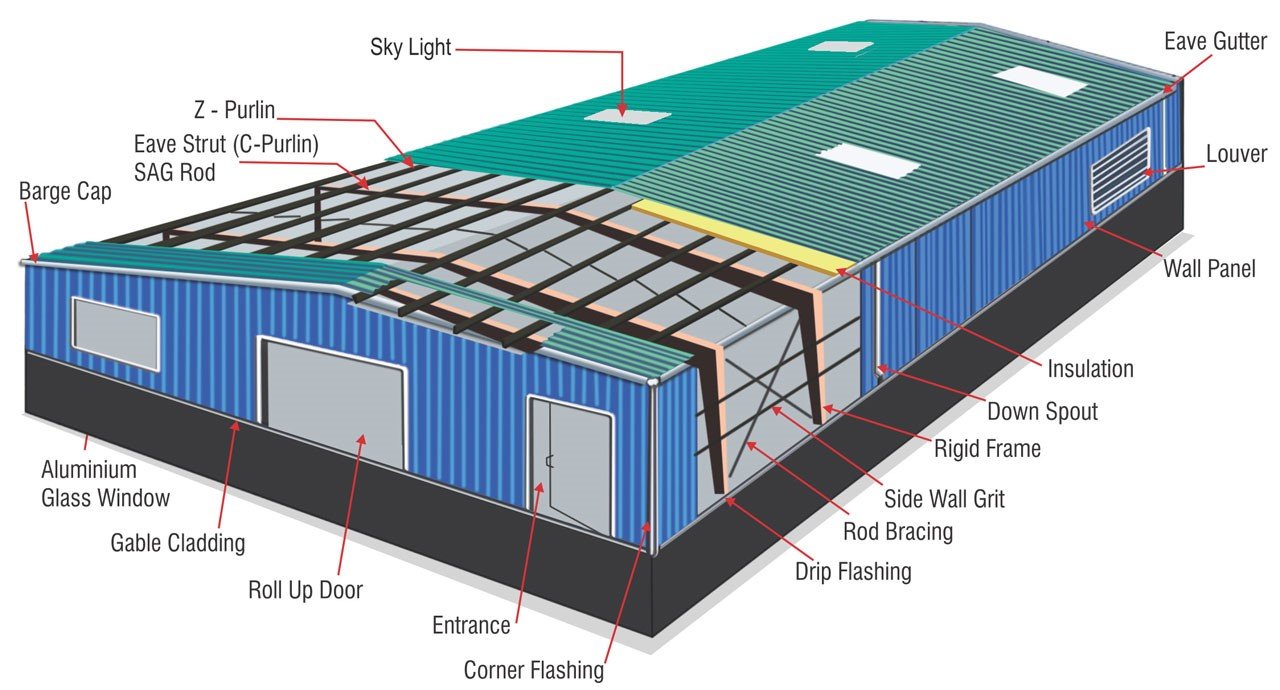

Nomenclature of Pre-Engineered Building / Metal Building.

- Reduce Construction Time

- Flexibility of Expansion

- Large Clear Span

- Low Maintenance

- Energy Efficient Roofing and Wall Systems

- Architectural Versatility

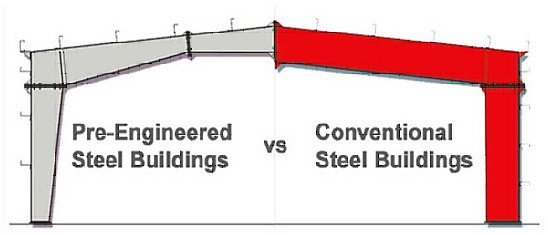

Conventional Frame Verses Pre-Engineered Rigid Frame

Frames of pre-engineered Building are constructed from a large inventory of standard steel plates that are stocked at the Pre-engineered Building. Pre-Engineered Building Frames are typically tapered, with variable-thickness flanges and web running the length of the individual members.

The Frame geometry matches the shape of internal stress (Bending Moment) diagram thus optimizing material usage and reducing the total weight of structure, also the entire rigid frame allows to sway in tolerable limit hence low reaction & moment. RCC rooting save the cost of RCC footing & pedestals.

In conventional steel Buildings, mill produce hot rolled sections (Beams & Columns) are used. The size of each member is selected because of the maximum internal stress in the member. The hot rolled sections have a constant depth, many parts of the member, in areas of low internal stresses, and are more than design requirements.

- Frame for Width – 24 to 40 M with two spans with two ridges

- Frame for Width – 48 to 96 M with four spans with single ridge

- Frame for Width – 36 to 72 M with three spans with single ridge

- Frame for Width – 24 to 48 M with two span single ridge

- Frame for Width – 6 to 60 M with single span single ridge

- Frame for Width – 3 to 18 M with single span single slope

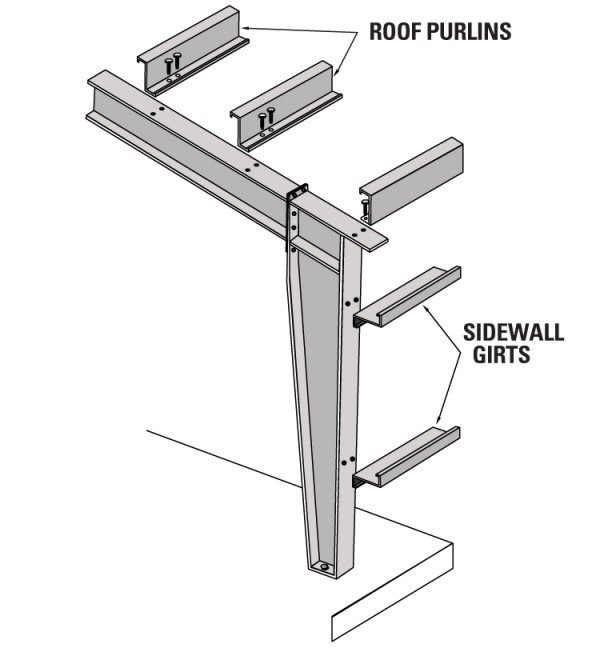

Secondary Member – Purling and Grits Cooled Rolled (Z & C Shape)

Secondary structural members such as purling, grits, and eave struts are used to reinforce the wall and roof panels. Purling is applied on the roof; grits are used on the walls and eave struts are used at the intersection of the sidewall to roof.

Secondary members have two additional functions:

- Provide lateral bracing to the main frame members’ compression flanges to enhance frame capacity.

- Assist in resisting part of the longitudinal loads that are applied to the structure, such as wind and earthquake loads, by acting as struts.

Purling, grits, and eave struts are available in high grade steel satisfy to ASTM A 607 Grade 50 or equivalent, available in 1.5 mm, 1.75 mm. 2.0 mm, 2.25 mm, 2.5 mm and 3.0 mm thickness. They come with a pre-galvanized finishing or factory painted with a minimum of 35 microns (DFT) of corrosion.

Application:

Warehouses, Factories, workshops, Offices, Gas stations, Show rooms, schools, vehicle parking sheds, Railway stations, indoor stadiums, bridges, aircraft hangars, community halls.

Combination

- 99.5 % Zn

- Al 55%Zn 43.4%Si 1.6%

- Al 55%Zn 43.4%Si 1.6%

Type of coating

- RMP/SMP

- RMP/SMP

- RMP/SMP

Base Metal

- High Tensile /CR

- High Tensile Steel

- RMP/SMP High Tensile Steel

Thickness

- 0.47 mm to .8mm

- 0.47 mm to 0.5 mm

- 0.47 mm to 0.5 mm